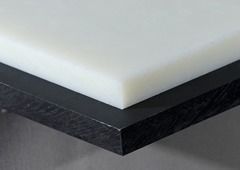

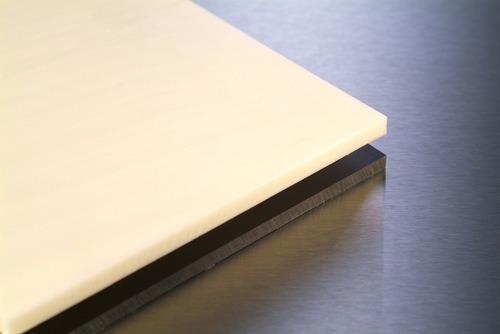

Cast Nylon Sheet

Product Details:

- Color Cream

- Usage Industrial

- Product Type Nylon Sheet

- Plastic Type Cast Nylon

- Plastic Molding Type Casting

- Shape Rectangular

- Warranty 1 Year

- Click to view more

Cast Nylon Sheet Price And Quantity

- 1 Kilograms

Cast Nylon Sheet Product Specifications

- Cream

- Rectangular

- Industrial

- Nylon Sheet

- 1 Year

- Casting

- Cast Nylon

Cast Nylon Sheet Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Days after Acceptance (DA) Delivery Point (DP) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Western Union Paypal Cash in Advance (CID) Cheque Cash Advance (CA)

- 2000 Kilograms Per Week

- Australia North America Eastern Europe Middle East Africa South America Western Europe Asia Central America

- All India

Product Description

Key points:

- Corrosion resistance

- Accurate dimensions

- Enhanced resilience

- Supreme finish

With years of experience, we are manufacturing and supplying a broad ambit of cast nylon sheets, which are normally superior to extruded nylon sheets. As these sheets are fabricated through polymerization of caprolactam, the compound has never been softened, thus, has been exposed to any heat degradation. Since physical attributes of Thermoplastics enhance with rising atomic weight ,it has higher compressive and tensile strength. Along with this, our cast nylon sheets possess significant features comprising greater toughness and modulus of flexibility, lesser distortion at elevated temperatures, better dimensional precision, good resistivity from solvents, etc. than extruded sheets.

The casting procedure improves the cast nylon sheets yet with lesser dampness assimilation and enhanced strength. It allows manufacturing of pressure-free stock forms of about unlimited extent. Further, our product likewise possess effective heat maturing characteristics, is retardant to mostly chemicals, cleaning fluids, oils and fuels and is electrically insulating.

Field of Applications

As our range of cast nylon sheets are more strong than any other compounded sheets, customers all around the world utilize our product in many things. The various industries and applications include roller coaster wheels, pharmaceutical, Railway- pads, bushes, etc. defense, coal mining, steel rolling mills, cable manufacturing, nuclear, hydraulics, bottling/brewing, paper/pulp, bearings, rope and wire accumulators, automotive, textile, packaging equipment, power sector, sugar mills, tobacco processing, electric, general engineering, constructions and hydropower civil facilitates, film processing, gaskets, bushings, etc.

Benefits of Our Product

- Energy saving and water retardant

- Light wight as compared to metal and simple machinability

- Resistivity against cracking, UV rays and pressure

- Possess hard and smooth surface

- Excellent di-electric strength and friction resistance

- Optimum impact strength and does not demand bearing seals

- Less coefficient of abrasion and rust resistant to most chemicals and acids

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese